Risk Control in Sintered Magnet ProductionZhaobao Magnetics, Ningbo China, Mining & Metallurgy

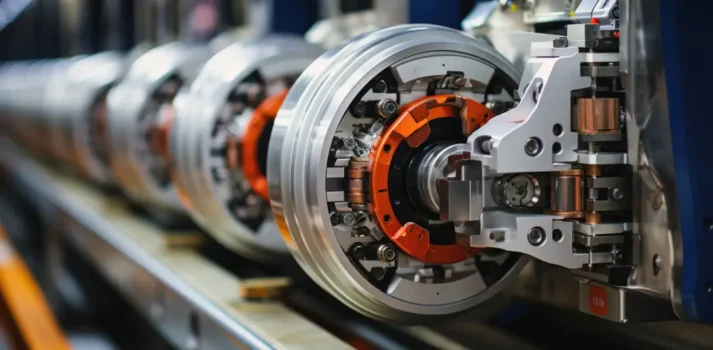

Zhaobao Magnet is a leading manufacturer of rare-earth permanent magnets in China, serving high-performance motor applications including compressors, servo drives, elevator motors, wind turbines, and EV traction systems.

Eddso supported the client through a Supplier Risk Control Project focused on powder forming, sintering bottlenecks, and final packaging alignment. The goal was to improve process safety, stabilize takt rhythm, and enhance inboard delivery performance.

Challenge

The pre-sintering and sintering processes presented safety and stability risks due to material sensitivity and long oven cycles. Final packaging was frequently reorganized due to magnet customization, and inboard delivery was inconsistent.

- Explosion-Prone Forming Operations

Orientation forming required special equipment and trained operators to mitigate risk. - Sintering Bottleneck

Oven release was slow and often mismatched with downstream demand. - Flexible Layout Pressure

Magnet shape variation caused constant layout changes in boxing and magnetization. - Poor Inboard OTD Control

Supplier delivery lacked scheduling standards and failed to meet takt requirements.

Solution

A targeted risk-control initiative was deployed across forming, sintering, and packaging areas to balance process safety and supply-chain resilience.

- Process Risk Checklist

Identified critical risks in forming and created operation-specific safety lists. - Sintering Flow Buffering

Added buffer zones and takt-based planning between ovens and final stages. - Modular Packaging Layouts

Introduced flexible magnetization and boxing modules to reduce reconfiguration time. - Delivery Control Routine

Set up weekly OTD review and 8D root cause tracking for inboard supplier issues.

- Process Risk Checklist

Results

Process compliance and supply stability improved within 8 weeks, creating measurable gains in takt rhythm and supplier collaboration.

- +20% Safety Compliance

High-risk operations aligned with corporate safety protocols. - +15% Output Rhythm

Sintering-to-packaging flow improved overall line balance. - 95% On-Time Delivery

Inboard supplier adherence rose with structured delivery governance. - Supplier Status Upgrade

Audit score reclassified the supplier into preferred-tier for strategic partnership.