Smart & Traceable – RFID-Enabled Standardized Folding Bins

Client

Mustang Group, China

Date

July 30, 2020

Services

Traceability & Transparency | Flow Optimization

Website

Major Improvments

- RFID-Embedded Bin Redesign

Developed in-house a series of durable, collapsible bins with embedded RFID tags for automatic tracking. - Digital Bin Lifecycle Management

Enabled real-time tracking of bin status: inbound, in-process, outbound, idle, or maintenance. - Automated Location Scanning

Integrated with warehouse and production floor gates to auto-scan bin identity without manual barcode intervention. - Error-Proofing Through Material Verification

Linked RFID IDs to production orders and BOMs, preventing part mismatches during line feeding.

Application Scope

- Inbound Material Control

Reduced receiving and sorting times by 30% through automated bin identification and classification. - Line-Side Feeding & Replenishment

Streamlined replenishment by tracking each bin’s location and usage in real time. - Inter-Process Logistics Transparency

Improved WIP traceability between machining, sub-assembly, and final stations. - Inventory & Loss Prevention

Minimized missing bin incidents and ensured inventory accuracy through daily bin movement logs.

Customer Says

Success Projects

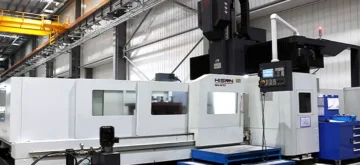

Smart Supply-chain Resilience in Gear Shaft Machining

Responsive Supply-chain

Restructuring Production & Logistics in Heavy Gearbox Manufacturing

Flow Optimization

National-Level Demonstration of Visual Transparency in Special Steel

Flow Optimization

TPM & VSM Upgrade for Battery Quality Compliance

Flow Optimization