MES Meets HR – Integrating Time Attendance & Auto Reporting

Client

AUO Group, China

Date

August 12, 2021

Services

Traceability & Transparency | Cost Deployment

Website

Major Improvments

- Unified Login System

Linked employee badge login to both MES terminal and attendance system, eliminating redundant scanning. - Auto Labor Reporting via Station Entry

Enabled task-based auto-reporting by detecting employee presence at specific workstations and matching to job code. - Daily Output vs. Labor Cost Analysis

Connected man-hour data with MES job outputs to visualize unit labor cost per product in real time. - Exception Alerts for HR & Production

Triggered real-time alerts for unusual absenteeism or reporting inconsistencies across shifts.

Application Scope

- Final Assembly Zone

Replaced manual paper sheets with terminal-driven labor traceability and task assignment. - Shift Start & End Optimization

Cut 10+ minutes of idle time per shift by eliminating double-login and job entry duplication. - Cost Deployment Reports

Fed live data into value stream costing models to better reflect actual labor consumption. - HR–Operations Alignment

Improved transparency between plant HR and production leadership through unified reporting dashboards.

Customer Says

Success Projects

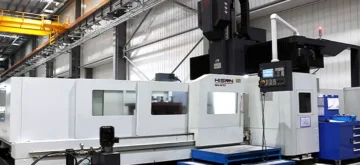

Smart Supply-chain Resilience in Gear Shaft Machining

Responsive Supply-chain

Restructuring Production & Logistics in Heavy Gearbox Manufacturing

Flow Optimization

National-Level Demonstration of Visual Transparency in Special Steel

Flow Optimization

TPM & VSM Upgrade for Battery Quality Compliance

Flow Optimization