Driving Efficiency – Organizing QCO & SMED Workshops

Client

Camel Group, China

Date

May 10, 2023

Services

Quick Changeover (SMED) | Flow Optimization

Website

Major Improvments

- Setup Time Reduction

By implementing a structured SMED methodology, we reduced average changeover time by 38%, significantly boosting OEE. - Visual Tooling Standardization

Created a visual toolbox and layout system for each machine station, enabling operators to follow best practices intuitively. - Internal vs External Activity Separation

Clearly identified and redistributed tasks into pre- and post-setup, minimizing machine downtime during changeovers.

Application Scope

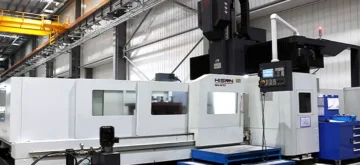

- Battery Assembly Line

Applied SMED principles to high-volume lithium battery lines, improving takt time in both single and dual-station setups. - Automotive Relay Production

Standardized quick change procedures in relay production, ensuring minimal variation between shifts. - Operator Training Modules

Developed short, visual-based training tools to help line leaders and new operators quickly grasp optimized changeover routines.

Customer Says

Success Projects

Smart Supply-chain Resilience in Gear Shaft Machining

Responsive Supply-chain

Restructuring Production & Logistics in Heavy Gearbox Manufacturing

Flow Optimization

National-Level Demonstration of Visual Transparency in Special Steel

Flow Optimization

TPM & VSM Upgrade for Battery Quality Compliance

Flow Optimization