Designing an Ergonomic Experience Zone – Where People Meet Processes

Client

Hager Group, China

Date

April 08, 2024

Services

Agility Operations | Delivery Transitional Leadership

Website

Major Improvments

- Muri & Ergonomics Simulation Station

Created real-life workstations simulating repetitive tasks to assess physical strain using posture scanning and force sensors. - Body-Machine Interaction Visuals

Displayed common ergonomic risks and good practices via physical demo stations and interactive screens. - Operator Co-Creation Sessions

Engaged frontline workers in co-designing improved tools and workstation heights for better fit and safety. - Lean-Linked Ergonomics Metrics

Integrated injury risk scores and fatigue indicators into the daily management board.

Application Scope

- Production Line Redesign

Used simulation data to redesign tool layouts and lifting supports across 3 engine assembly lines. - Operator Training & Awareness

Standardized ergonomic onboarding for new hires, reducing complaint rate by 38%. - Health & Safety Campaigns

Built the zone into HSE Week activities to reinforce safe and sustainable working behavior. - Improvement Project Validation

Acted as a testbed for ergonomic Kaizens before rolling out changes to real workstations.

Customer Says

Success Projects

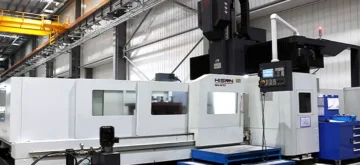

Smart Supply-chain Resilience in Gear Shaft Machining

Responsive Supply-chain

Restructuring Production & Logistics in Heavy Gearbox Manufacturing

Flow Optimization

National-Level Demonstration of Visual Transparency in Special Steel

Flow Optimization

TPM & VSM Upgrade for Battery Quality Compliance

Flow Optimization