Designing a World-Class Lean Academy – From Vision to Execution

Client

FCA Group, Italy

Date

March 12, 2018

Services

Agility Operations | Sustainability & Resilience

Website

Major Improvments

- Modular Space Planning

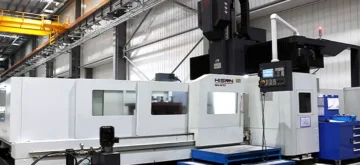

Designed a fully modular lean training space layout inspired by FCA Turin’s Academy blueprint, enabling scalable and flexible training zones. - Learning by Doing Flow

Established a U-shaped flow layout for live simulations of production, logistics, quality gates, and changeovers. - Role-Based Training Structure

Developed tiered curriculums for operators, team leaders, and engineers based on real shopfloor use cases. - Integration of KPIs & Daily Management

Embedded visual performance boards, hourly tracking routines, and digital PDCA corners for habit formation.

- Modular Space Planning

Application Scope

- New Employee Onboarding

Used as a bootcamp to immerse new hires in practical lean methods before entering real production lines. - Improvement Project Showcases

Provided a physical platform to demonstrate Kaizen projects, increasing engagement and organizational learning. - Supplier Capability Audits

Served as a verification hub to assess supplier understanding of WCM principles before nomination. - Leadership Coaching Arena

Enabled structured leadership walkthroughs and mentoring sessions based on real-time production simulation.

Customer Says

Success Projects

Smart Supply-chain Resilience in Gear Shaft Machining

Responsive Supply-chain

Restructuring Production & Logistics in Heavy Gearbox Manufacturing

Flow Optimization

National-Level Demonstration of Visual Transparency in Special Steel

Flow Optimization

TPM & VSM Upgrade for Battery Quality Compliance

Flow Optimization