Delivering Value Through VSM – Unlocking Process Potential

Client

Hager Group, China

Date

Jun 17, 2022

Services

Cost Deployment | Flow Optimization

Website

Major Improvments

- Cross-functional VSM Workshop

Facilitated a hands-on workshop to align functions and map the entire process from customer order to shipment. - Non-value Activities Identification

Detected redundant checks, rework loops, and idle time, enabling direct elimination or merging of tasks. - Data-Driven Process Timing

Introduced actual takt-time tracking across key steps, supporting fact-based improvement prioritization. - Improvement Implementation Tracker

Built a visual kanban system to follow-up actions and sustain continuous improvements.

Application Scope

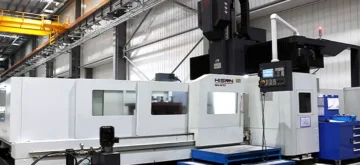

- Metalworking Line (Components & Assembly)

Mapped material and information flow across stations, reducing throughput time by 24%. - Assembly Final Test

Identified bottlenecks in final testing and packaging, unlocking layout improvement opportunities. - Customer Service Interface

Clarified order handling delays via flow-back analysis from dispatch to intake. - Process Value Improvement

Linked VSM outcomes to real-time Process Value (Labor, Materials, Expenses) for ongoing decision-making relevance.

Customer Says

Success Projects

Smart Supply-chain Resilience in Gear Shaft Machining

Responsive Supply-chain

Restructuring Production & Logistics in Heavy Gearbox Manufacturing

Flow Optimization

National-Level Demonstration of Visual Transparency in Special Steel

Flow Optimization

TPM & VSM Upgrade for Battery Quality Compliance

Flow Optimization