Cost Deployment in Action – Structuring Losses under WCM

Client

Getrag Group, China

Date

March 15, 2019

Services

Cost Deployment | Sustainability & Resilience

Website

Major Improvments

- Full Loss Tree Mapping

Structured all losses into categories (Productivity, Quality, Energy, Logistics), creating a full WCM-aligned cost tree. - Data-Driven Prioritization

Used historical cost records and actual incidents to rank top contributors to total cost per unit. - Cross-Functional Deep Dive

Engaged production, finance, quality, and logistics teams in a joint analysis of root causes behind critical losses. - Deployment Board Setup

Built a visual board system to track top 20 cost drivers and link to targeted improvement projects.

Application Scope

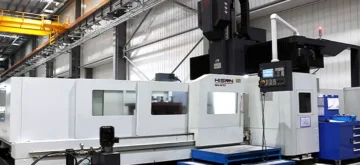

- Machining Cell – Quality Loss Focus

Identified most frequent scrap causes and quantified financial impact using cost-per-defect indicators. - Assembly Line – Time Loss Analysis

Uncovered setup time waste and idle machine intervals, assigning monetary loss to each source. - Energy Cost Deployment

Deployed energy monitoring per station and linked excessive use to specific shift/time blocks. - Lean Budget Integration

Connected cost deployment results with the site’s lean annual budget and kaizen prioritization plan.

Customer Says

Success Projects

Smart Supply-chain Resilience in Gear Shaft Machining

Responsive Supply-chain

Restructuring Production & Logistics in Heavy Gearbox Manufacturing

Flow Optimization

National-Level Demonstration of Visual Transparency in Special Steel

Flow Optimization

TPM & VSM Upgrade for Battery Quality Compliance

Flow Optimization